How the Best PCB Stencil Manufacturers Create their Products

Stencils are thin sheets usually made of metals or polyimides. They feature aperture formations that dictate how different PCB components are laid out. A soldering professional will use a PCB stencil to precisely deposit appropriate amounts of solder paste on the PCB board. PCB stencils make it possible for soldering professionals to carry out paste deposition processes in one attempt. When they remove the stencil, the solder pastes deposits sit perfectly aligned with the stencil’s apertures. Then, a surface-mount device can be directly installed on the PCB board as the solder paste deposits are already in place to create the perfect adhesive bonds. The immaculate deposition of solder paste certifies that the solder joints are perfect in terms of mechanical strength and the ability to facilitate electrical connections.

The Importance of PCB Stencils

Surface Mount Technology is the standard procedure used by all equipment and device manufacturers. SMT makes it easier to deal with super-small components. Manufacturers can make more connections per component using SMT as components can be positioned on either side of the PCB.

Without PCB stencils, SMT is impossible. A good stencil can make SMT and PCB assembly processes seamless and time-efficient. Of course, the success of SMT production processes also depends on good condition equipment, good workmanship, etc. But, stencils start off all the other production processes, so it’s vital for assembly professionals to ensure they’re using high-quality stencils that are suitable for the job at hand.

If an SMT production process involves the use of a high-quality SMT stencil, there are 60% to 70% lesser chances of SMT defects. Be it the accurate placement of an SMD or minor solder defects – high-quality PCB stencils help assembly experts and PCBA engineers avoid all types of defects.

Hence, partnering with the best PCB stencil manufacturer should be every soldering or assembly professional’s priority. The top PCB stencil manufacturers can create customized PCB stencils for specific PCB pads. However, PCB stenciling is a procedure practised by thousands of professionals across the country. That’s why soldering professionals are advised to learn how to work with standardized PCB stencils – the ones that are used across the electronics manufacturing industry.

The IPC-7525A Stencil Design Guidelines is a document that all soldering professionals must understand. It outlines what types of stencils need to be used for producing what types of surface mount devices. The document mentions little details like how much solder paste the assembly professionals should ideally use, how different surface-mount adhesives operate, etc. All stencil manufacturers abide by the IPC-7525A Stencil Design Guidelines while manufacturing their products.

Stencil Manufacturers – What Details Do They Consider?

There are a few fundamental details that stencil manufacturers consider before manufacturing their products. They include –

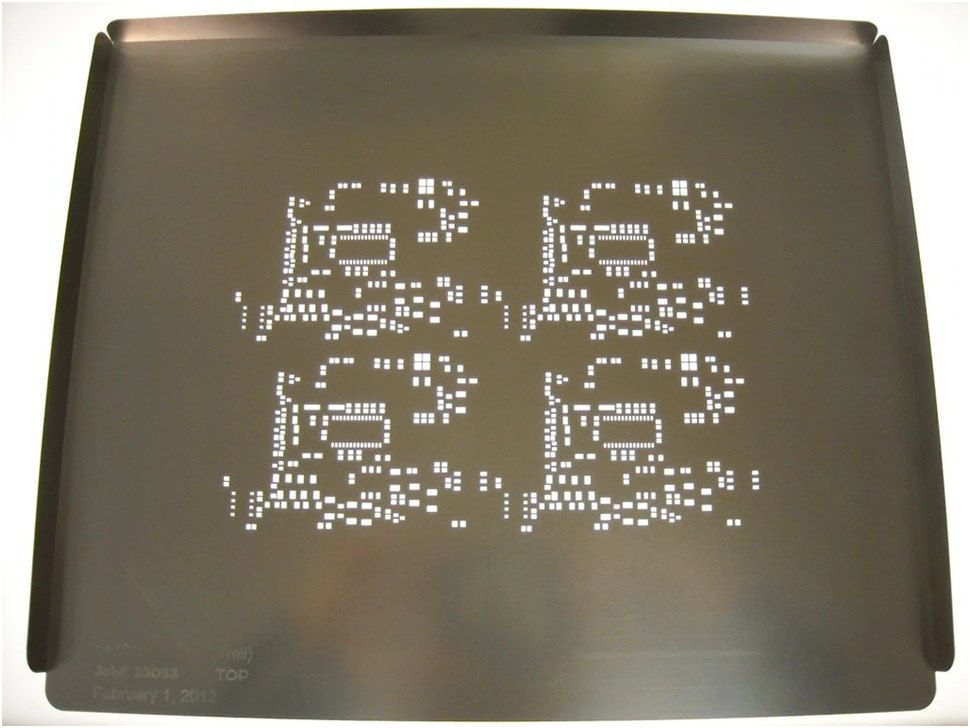

Using the Finest Materials

The material used to manufacture a PCB is critical to the PCB stencils’ design and their ability to facilitate assembly processes successfully. Most PCB stencils are super-thin and made of stainless steel. Stainless steel isn’t brittle. Hence, it’s easy to create accurately-sized apertures on stainless steel PCB stencils. Plus, stainless steel has a well-defined molecular structure. The aperture walls on stainless steel PCB stencils are extremely smooth. Solder deposition through these smooth apertures is very effortless.

However, stainless steel PCB stencils are very expensive. Their costs can take a toll on the production budget. That’s why many manufacturers are now using polyimide to create their products. Polyimide stencils are easy to manufacture, thanks to laser cutting technology. It’s also possible to create precise and smooth apertures on polyimide stencils. Polyamide stencils are significantly cheaper but less durable than stainless steel stencils.

The Type of Stencil

There are two types of PCB stencils – framed and frameless. Framed stencils are used mostly in high-volume and repetitive PCB printing processes. The stencil foils are cut with lasers to create very smooth and precise aperture walls. The foils are then fixed permanently in stencil frames. So, if an assembly team is working on a strict deadline, they’ll be advised to use framed stencils and automated printing devices.

On the other hand, frameless PCB stencils are ideal for short PCB production operations. These stencils are also created using laser cutting. Since there are no frames, storing these stencils becomes much easier. The smooth apertures on frameless PCB stencils also make them ideal for working with small components. You want a stencil manufacturer who specializes in manufacturing both framed and unframed PCB stencils.

Additional Coatings on Stencils

With certain types of coating, recurring problems common in PCB stenciling processes can be avoided. For instance, high-performance Nano-coating can help increase paste transfer efficiency and ensure residual solder in aperture walls don’t distort the needed solder paste-flux formulation. Other types of coating make it easier to clean PCBs after long production runs. Top PCB stencil manufacturers offer their clients different types of coating options.