From Solder Balls to Solder Excellence: Understanding BGA Reballing

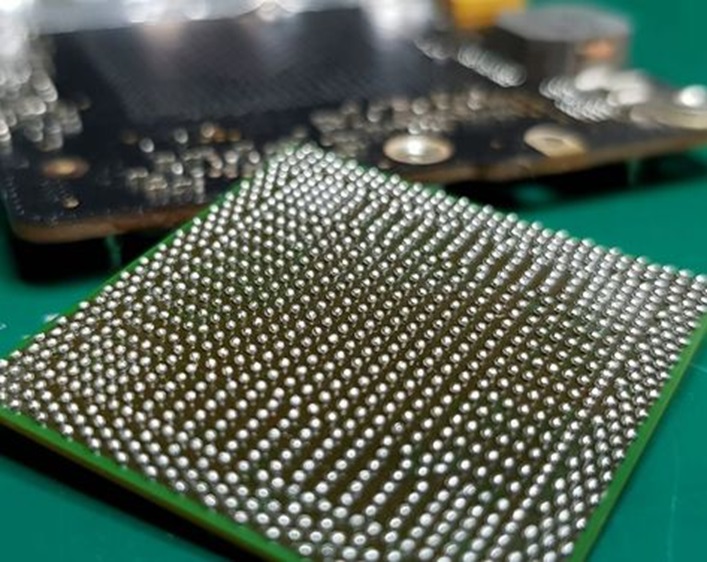

In the electronics manufacturing and repair industry, Ball Grid Array (BGA) components are becoming more popular because they are very small and perform better than other options. However, when these complicated parts stop working or need to be improved, BGA reballing is what fixes them and makes them work again. In this post, we will explore the interesting process of BGA reballing. We will learn why it is important, discover the techniques involved, and understand how it turns solder balls into solder excellence.

What Does BGA Reballing Mean?

BGA reballing is a process used in electronics manufacturing and repair. It includes taking out and replacing small solder balls on a Ball Grid Array (BGA) part. BGAs are used a lot in today’s electronics because they are small and easy to fit into devices. When a BGA component stops working or needs to be improved, reballing is used.

The process involves taking out a part carefully, removing old solder balls, cleaning, putting in new ones, heating them to make them stick together well, and carefully checking and testing everything. BGA reballing service is a low-cost and eco-friendly way to maintain the quality and lifespan of electronic devices by keeping the solder connections strong and reliable.

BGA Reballing Process

Removing Components: The first thing we do is take off the BGA component from the circuit board with great care. This needs accuracy and specific tools like a hot air rework station.

Removing Solder Balls: After separating the BGA component, the solder balls currently present must be taken out. Usually, we heat the part and gently remove the old balls of solder.

Cleaning of Components: Once the BGA component and the circuit board are taken out, they are carefully cleaned to make sure that no leftover solder or impurities remain.

Placing Solder Balls: The new solder balls, which need to be the right size and made of the right stuff, are carefully put onto the BGA part. This step needs to be done carefully and with extra attention so that everything lines up correctly.

Reflow: The BGA component is heated and melted using a special oven or hot air tools. This heats up the solder balls, making them stick firmly to the part and the circuit board.

Testing: The last step includes carefully examining and testing to make sure the fixing of the component was done well and that it works as it should.

Significance of BGA Reballing

BGA (Ball Grid Array) reballing is an important process in electronics manufacturing and repair. It is very significant. Here’s why fixing BGA soldering is important:

Affordable Fixes: BGA parts are commonly found in intricate electronic devices, and getting a whole new circuit board can be costly. Reballing helps fix specific problems and saves a lot of money.

Sustainability: BGA reballing helps the environment by making electronic components last longer. This helps prevent electronic waste and supports a more environmentally friendly future.

Upgradability: As technology advances quickly, older parts might not be able to handle the needs of newer software or tools. BGA reballing is a process that helps upgrade components in devices. It makes sure that existing devices can easily be adjusted to work with the latest technology.

Quality Assurance: BGA reballing is not only about fixing things but also about making sure the work is done to a high standard. To complete the task correctly, you need to be very careful and pay close attention to small details. This will help make sure that the solder connections are strong and dependable.

Prompt Repairs: Often, having to replace a whole printed circuit board or device can cause a lot of time where the device is not working. BGA reballing is a repair process that aims to reduce time without use and keeps electronic devices working.

Future of BGA Reballing

The way we fix and improve BGA is getting ready for new and better changes because electronics are always getting better. As electronic devices get smaller and more complicated, the way BGA reballing service is done will have to change too. This is necessary because the parts and solder balls used are getting smaller. Automation could be used more to make the reballing process smoother and more accurate.

Furthermore, environment-friendly solder materials and methods might become more popular to support sustainability objectives. As electronics become more and more a part of our everyday lives, BGA reballing will continue to be important in making electronic parts last longer and work better.

Conclusion

BGA reballing is the process that connects solder balls with high-quality soldering in the field of electronics. This task requires a lot of attention to detail, skill, and the correct tools. Understanding the significance of BGA reballing helps us see how it helps save money, supports sustainability, and improves the overall quality of electronic devices. In a time when electronics are constantly getting better and changing quickly, BGA reballing is an important technique. It helps fix old parts and makes sure they can keep up with the new technology.