A Complete Guide to Cool Room Installation

A cool room enables your products to stay fresh and durable for a long time. But you must consider some factors and requirements to ensure you get the best cool room installation. The installation of cool rooms is now an essential component used in many facilities. They have simplified storing and preserving solutions for a wide range of goods and materials as they occupy significantly less space and energy than any other cold storage option.

Types Of Cool Room?

As the name suggests, a cool room can store things that need to be in a calm or cool environment to stay fresh or live longer.

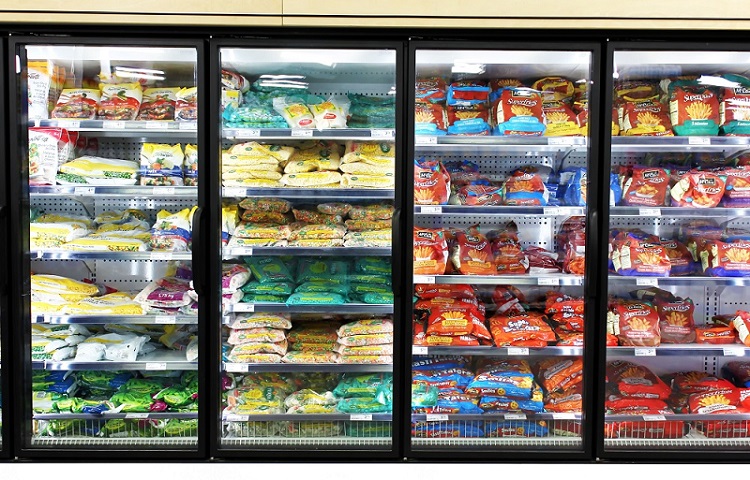

The first type is ‘long-term storage,’ a building or portion of a building specifically developed for storing goods for extended periods. Supermarkets are an excellent example of a business that necessitates long-term cold storage.

The second type of storage is provisional or short-term cold storage commonly referred to as fridge rental.

Frozen storages are the third type.

Cool room installation guide:

Before starting with the installation of the cool room, it is necessary to consider certain requirements. Following are some of the basic factors one must keep in mind.

Location of cool room:

-

Away from direct sunlight

The room must be established in confined quarters with very little air movement and flow. The refrigeration unit must not be installed in places exposed to direct sunlight, and the surrounding temperature should not surpass 43 degrees Celsius. The location is an important criterion you must consider before cool room installation.

-

Spacing:

You must also leave some space in front for the door to open and close properly. Swing doors, for instance, require enough space to operate freely because they are pre-aligned and fastened.

-

Surface:

The device must also be installed on a level surface to avoid panel imbalance and allow the gate to close completely. A 5mm allowance may be made on each end of the floor.

Cool Room Installation on Existing Uninsulated Concrete

If the layout is square, the difference in diagonals from one corner to the next should not exceed 3mm. Keep a 25mm gap from walls in case of mistakes. Cut the aluminum base “F” into a square and compound and shape the corners to fit the doorways. Then, along the boundary of the room or planned construction area, apply a 300mm wide strip of polythene along with 10mm resin to the cement floor. Apply resin beneath the aluminum “F” base and secure it to the concrete with the help of 400 mm wide tappets. Keep the aluminum base straight along the discontinued edges to ensure continuous alignment.

Cool room installation on an Insulated Concrete Floor

Begin by laying out the 300mm-wide polythene strip on the concrete floor. Apply it around the inside of the metal base and the edges. Then, place the polythene strip on the upper edge of the resin bead and secure it to the aluminum mold and concrete. Continue erecting the wall section.

Conclusion:

Cool room installation is an effective long-term cost-cutting measure because it prevents specific products from expiring too soon. They have a wide range of applications. You must take the time to consider your prerequisites to ensure that you get the best one for your requirement. You should also make certain that it is well managed to be efficient and operational in the long run.