8 Things To Consider To Choose The Right Electronic Weighbridge Supplier

A weighbridge is a significant capital investment. Hence, before you get it calibrated and installed, you need to consider certain essential factors. It is crucial to get a site survey and specify its build type and design according to the environment and use so that you can maximize its efficiency and durability.

To facilitate your weighbridge’s management, operations, and maintenance, you need to choose the right supplier. It would help if you worked closely with your vendor to adopt an appropriate strategy to select the right weighbridge type and suitable location for installment.

To determine the right place, you should ensure that the weighbridge includes proximity to a port-of-entry (border post or a port) or generators of heavy vehicle traffic, like industrial areas, so that you can minimize the escape routes and reduce overloading. You need to check the economic viability of the location. And, to choose the right weighbridge type, assess if the site is fit for excavation work, and accordingly, you can select a pit or pitless weighbridge. If you need to relocate your weighbridge from time to time, you can also choose a portable weighbridge.

Different types of custom-built are available in the market, such as heavy vehicle weighbridge, cattle weighbridges, rail weighbridges, in-motion weighbridges, axle weighbridges, and wheel weighers. These weighbridges are operated digitally and use load cells for measurement. However, selecting the right supplier for your weighbridge can be daunting. To choose an electronic weighbridge supplier manufacturers for your business, consider the following points.

Business Needs

What is your objective to implement a weighbridge into your business? What kind of vehicles will your weighbridge support? If it is for smaller cars, you can use a lighter weighbridge or axle weighing pads. How will the weigh-in-motion feature and data acquisition system of electronic weighbridges support your business goals? You need to check both the short-term and long-term goals of integrating a weighbridge into your business to analyze if you are making the right choice.

Compliance

You should ensure that your weighbridge manufacturer/supplier is legally authorized to build and supply weighbridges for legal enforcement purposes. In addition, it should cover the verification and calibration process not to breach the standard regulatory guidelines while operating your weighbridge.

Types Of Load Cells Used

The load cells convert the vehicle’s weight into an electric signal processed by the weight indicator. Load cells differ in size, shape, capacities, and performance. You need to determine if you need analog or digital load cells. Ensure that the load cells fulfill the accuracy criteria set by the relevant certifying bodies. Your vendor should efficiently assess the accuracy of the load cells.

Right Software

Your vendor should develop software that can seamlessly integrate your business platform. It should accommodate the back-office systems and intelligent weight indicators to analyze and store data so that you can add value to your weighbridge system. The software should be able to collect, analyze efficiently, and process transactional scale weighment data.

Customization

The vendor should allow you to customize your weighbridge to fit your business needs. A one-fits-all approach is redundant, and it may fail to deliver optimum performance. It would help if you customized various aspects like type, size, capacity, load cells, and even paint finish of your weighbridge.

Security Support

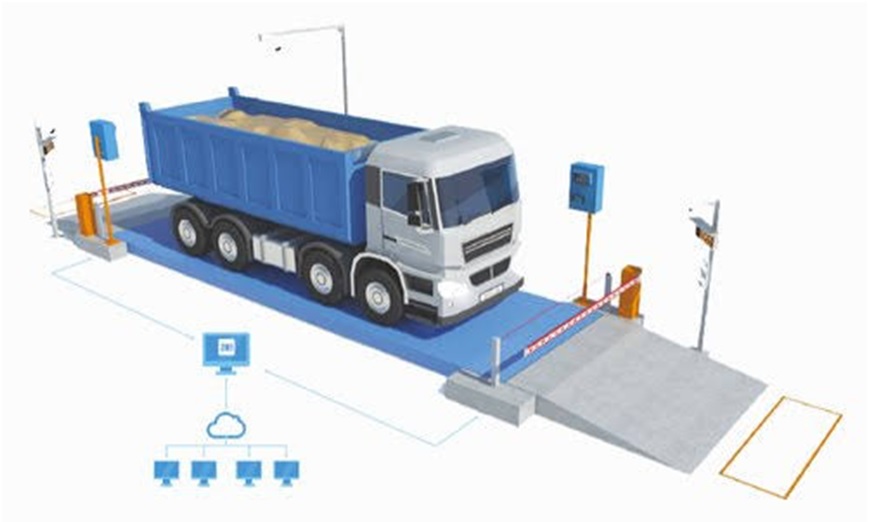

Additional support into your weighbridge systems such as boom barriers at weighbridge entry and exit stations, variable message displays or traffic lights, voice guidance to manage traffic flow, and sensors enable you to control the movement of vehicles on your weighbridge. Other features like camera surveillance at weight recording and RFID (Radio Frequency Identification) help identify weighbridge theft and fraud. With these features, you can monitor, organize and manage data efficiently.

Measure On- Or Off-Site

Your vendor can help you identify if you will benefit more from installing a weighbridge on or off-site. On-site weighbridges are helpful for miners, quarries, recycling centers, and other such industries. Depending on how the weighbridge will help you drive growth and revenue, you need to plan the weighbridge project accordingly.

Build Quality And Design

Ensure that the weighbridge is manufactured according to the recognized ISO standards. If it is to be used in chemical and petrochemical facilities, ask your manufacturer to provide certifications for operating in hazardous zones. Weighbridges are used in rough working conditions and harsh climates.

The manufacturer should confirm the use of Plasma Cutting, MIG Welding, NDT Testing, Shot Blasting, Protective Coating, Epoxy Finishing for the better build quality of the weighbridge. It will significantly improve the longevity of the weighbridge. It should be calibrated with stringent quality standards, and the load cells should be adequately tested. The design of the weighbridge should support the end-use in the environment in which it is to be operated.

To Conclude:

Since weighbridges are long-term investments, you need to select the right vendor through strategic planning. Taking care of these factors while choosing the right supplier for your weighbridge will ensure continued accuracy and maximization of product lifetime.