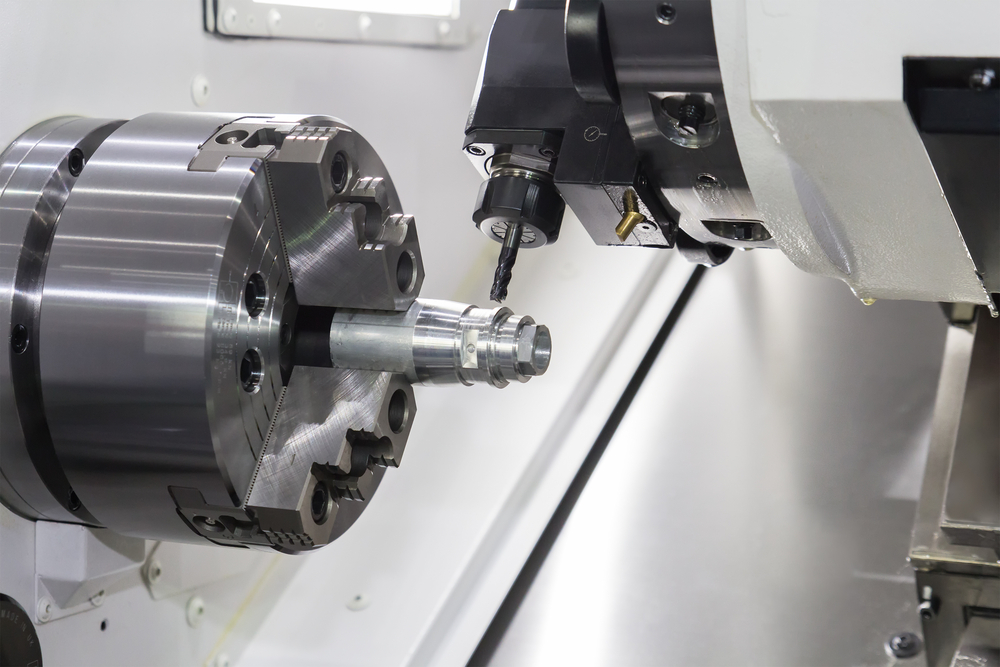

The Workable Efficacy of the CNC Machine Parts

Going for the right CNC machining services is essential for the possible accomplishment of the job. The parts are available in various speeds, shapes and sizes. The dimension of the CNC machine tool is admirable. This is the best gadget in hand widely used in the field of precision engineering and also at various manufacturing units. The machine is absolutely indispensable for using on shop flooring and comes with the array of vital uses and functionalities. The parts are just appropriate for use in molding and dyeing and also in the fabricating of complex medical items. It can also deal with the automobile and the aircraft parts with the best of its working efficacies.

Things to Consider While Using CNC Parts

To make use of the CNC parts you need to first consider the current set up of the machine. There are more things to consider as mentioned in points.

- You should take into account the experience of the engineer and the operator who is dealing with the CNC machine tools.

- In case you have old machines in possession then it is a time that you evaluate the capacity of the tool for manufacturing.

- You must see to the current gaps and take the initiative to enhance the life span of the machine.

- You must also evaluate the cost effectiveness element associated with the replacement of the existing machine with a new high performing model.

- The proficiency and expertise of the machine tool operator is highly vital. However, automated smart machines will require the least human intervention.

The Variety in Parts

The CNC parts come with some of the preferred Horizontal Tuning Centers for making a complete selection.

- First, you have the Cutex Range with the Linear Guide Way System. This is suitable for the wide range of applications and also for the production necessities. The Cutex is available in 2 to 5 Axis.

- Second, you have the Hi-TECH Line along with the Solid Hand Scrapped Box Guide Ways. This is the most suitable handle made from the toughest materials and utilizing the highest level of precision.

- There are the Multi-Axis Tuning Centers, and these are always the right choice in which case the complex parts are needed for the successful completion of the part in one setting.

More about the CNC Parts

Among the vital CNC parts, you have the Vertical Tuning Machines which are highly effective machinery parts with the bigger diameter. Some common examples are gear wheels, drums, pump housing, disk, engine housing and the rings. These parts are made to work right for the sake of production in both the High Mix and the Low Volume Mode along with the fastest turnaround of the various CNC parts are required for the exact machine setting. You also have the 5-Axis Machining Center D2-5AX and this offers the incredible solution in relation to the specifications of ø600mm 2-axis table, 4+1 to full 5-axis and 4 selectable spindles.

Dealing with the Materials

The CNC parts have the ability to work virtually with most of the materials including copper, aluminum, mold steel and many others. The parts can even deal with metals like hard steel, Inconel and Titanium. However, based on the type of metal the parts have the ability to influence their design and the selected spindle. The parts can even deal with the level of performance and the durability factor of these materials.

The CNC Machine parts are available along with a perfect control system. They offer better reliability of the CNC controls and high level of working effectiveness in the controls. The parts offer software ability, and these are also known for their user friendliness. In fact, based on the level of control you can find operators to deal effectively with the machine parts in real time.